Compressed Knitted Wire Mesh

Quick Service Request

Send Inspection Request

Compressed knitted wire mesh is a type of material made from knitted wire that has been compressed or compacted. Knitted wire mesh is a versatile material composed of interlocking loops of wire, typically made from materials like stainless steel, copper, or other metals. It is widely used in various industrial applications, including filtration, sealing, gaskets, insulation, vibration dampening, and more.

When the knitted wire mesh is compressed, it undergoes a process that reduces its original thickness and increases its density. The compression process involves applying pressure or passing the material through specialized rollers, resulting in a tighter and denser structure. The compression can be done either partially or uniformly across the entire mesh.

Compressed knitted wire mesh finds applications in various industries, including automotive, aerospace, chemical processing, oil and gas, electronics, and more. Its unique properties make it suitable for demanding environments where high strength, filtration efficiency, and reliability are required.

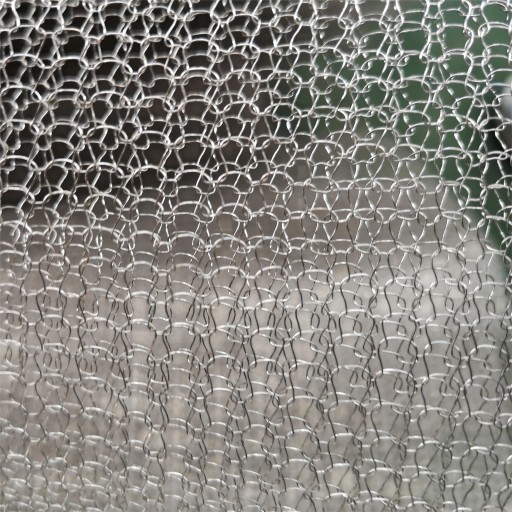

CPKWM-01

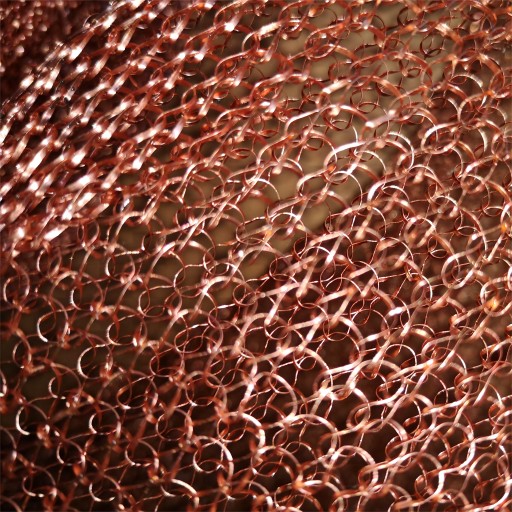

CPKWM-02

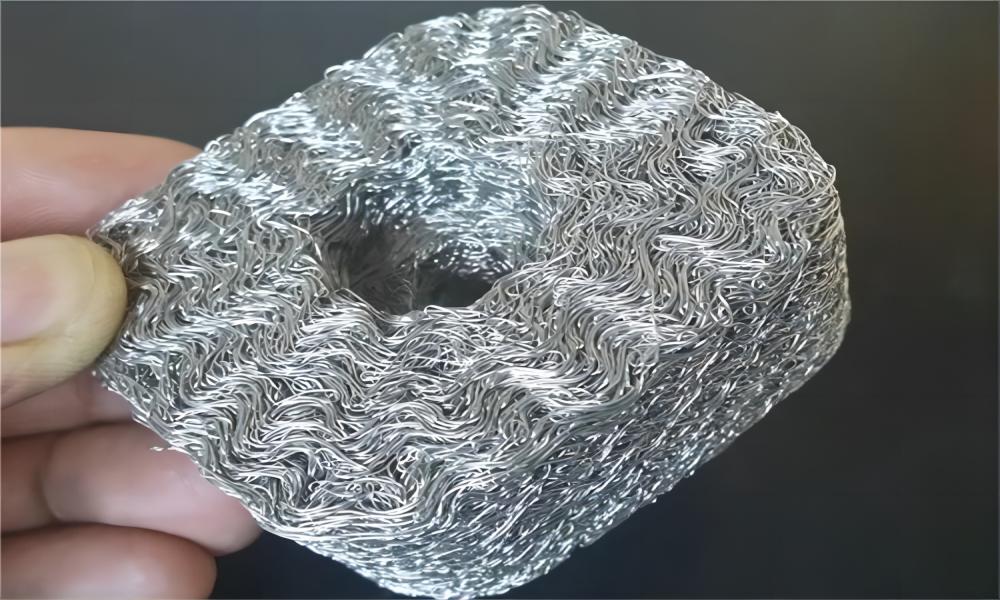

CPKWM-03

Materials

SS304、SS304A、SS316、SS316L、Monelse、Copper、etc.

Mesh Sizes

Compressed Knitted Wire Mesh comes in various shapes and sizes, which can be customized according to drawings and technical requirements. It is produced by compressing knitted wire with a diameter of 0.1-0.35mm, greatly enhancing the material’s mechanical strength and filtration efficiency.

Properties Of Compressed Knitted Wire Mesh

1、Enhanced Filtration: The compressed structure increases the number of wire loops per unit area, improving the mesh’s filtration efficiency.

2、Improved Strength: The compression process enhances the material’s mechanical strength, making it more durable and resistant to deformation.

3、Enhanced Sealing: The denser structure helps create a better seal in applications where effective sealing is crucial, such as gaskets and seals.

4、Increased Surface Area: Compression increases the mesh’s surface area, which can be beneficial for certain filtration and catalytic applications.

5、Better Heat Transfer: The compressed mesh can provide improved heat transfer characteristics due to its increased density.