PP-Demister Pad

Quick Service Request

Send Inspection Request

PP-Demister Pad is a device used to remove foam or bubbles from liquids. In many industrial and processing applications, foam may be generated in liquids, typically water or other solutions, which can affect production efficiency, product quality, or process stability. PP-Demister Pads are common devices used to address such situations.

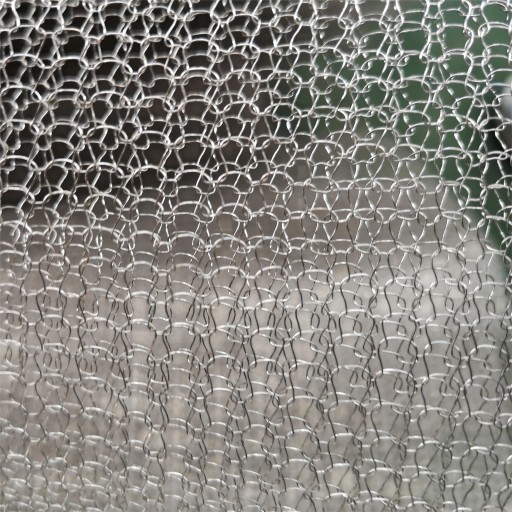

PP-Demister Pads are made of polypropylene, a common plastic material, and are used as the construction material in making them. A typical PP-Demister Pad consists of a container through which the liquid flows. Inside the container, there are usually some structures or components that help gather the foam together and separate it from the liquid surface. The foam can then be collected or discharged to other treatment facilities, effectively separating it from the liquid.

The design and principles of operation of PP-Demister Pads may vary depending on the application, but the overall objective is to facilitate the detachment of foam from the liquid using polypropylene material and specific constructions. This can be achieved through gravity, centrifugal force, bubble coalescence, or other mechanisms.

PPDP-01

PPDP-02

PPDP-03

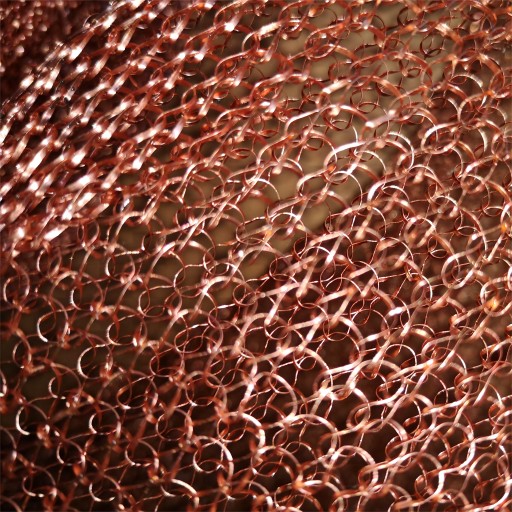

Materials

PP、PEFT

Mesh Sizes

PP- demister has a diameter range varying from 20 cm to several meters. It can be customized according to customer requirements, available in circular, square, or irregular shapes, all of which can be tailored based on provided blueprints. The wire diameter ranges from 0.1 to 0.3mm, and the density can be adjusted as per your needs. The maximum operating temperature can reach 120 degrees Celsius or even higher.

Properties Of PP-Demister Pad

1、The design and principles of operation of PP-Demister Pads may vary depending on the application, but the overall objective is to facilitate the detachment of foam from the liquid using polypropylene material and specific constructions. This can be achieved through gravity, centrifugal force, bubble coalescence, or other mechanisms.

2、Polypropylene is relatively lightweight and easy to process, making the manufacturing and installation of the demister pad more convenient.

3、PP-Demister Pad exhibits good resistance to various chemicals, including acids, alkalis, solvents, and more.

4、Polypropylene has very low water absorption, enabling it to maintain its performance and stability in humid environments or when in contact with water.

5、 PP-Demister Pad can operate within a relatively wide temperature range, displaying excellent heat resistance.