"Understanding Air-Liquid Filtration Mesh: Knitted, Foam-Breaking, Packing, and Foam-Suppressing"

An air-liquid filtration mesh is also known as a knitted mesh, foam-breaking mesh, packing mesh, or foam-suppressing mesh. These terms are often used to describe different characteristics or purposes of this type of filtration mesh.

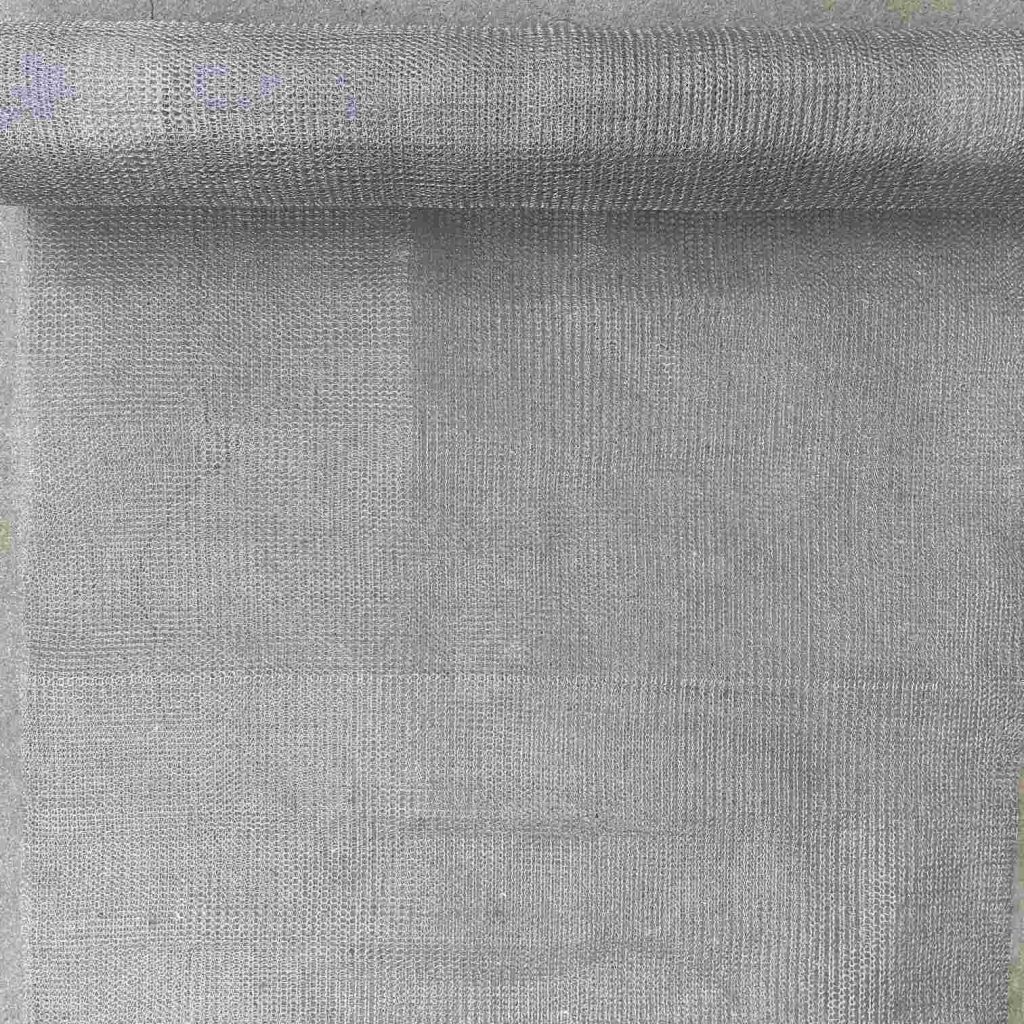

Knitted Mesh: Refers to the fact that this type of filtration mesh is typically made from a fabric or net-like structure, similar to knitted material.

Foam-Breaking Mesh: This term implies that one of the main purposes of this filtration mesh is to remove foam or bubbles from liquids to enhance liquid purity.

Packing Mesh: This might be because some air-liquid filtration meshes are used as packing to increase the surface area in reactors or other devices to promote reactions or separation processes.

Foam-Suppressing Mesh: Similar to “foam-breaking mesh,” it might indicate that this filtration mesh is used to address or mitigate foam-related issues.

Regardless of the terminology used, air-liquid filtration meshes are widely employed in industries such as industrial, chemical, food and beverage, etc., to filter and separate solid particles, foam, or other impurities from gases and liquids.