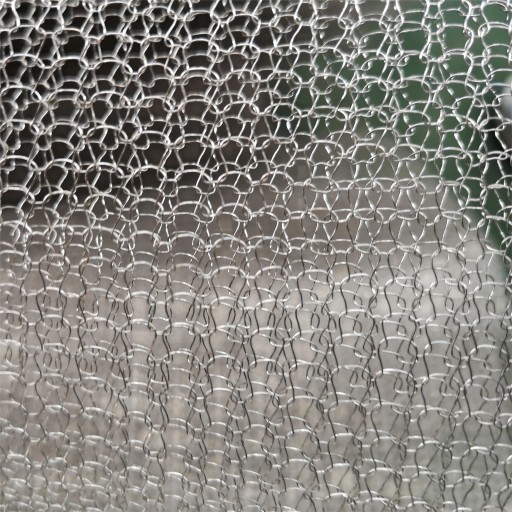

Stainless Steel Demister Pad

Quick Service Request

Send Inspection Request

Demister pad is a device commonly used for liquid treatment to remove foam or suspended solid particles from the liquid. It typically consists of a perforated metal wire mesh, and when the liquid passes through this wire mesh, the foam and solid particles are trapped on the surface of the mesh, achieving the purification and defoaming effect of the liquid.

The working principle of a demister pad is simple: the liquid enters the demister pad through the inlet, and as it passes through the wire mesh, the foam is retained on the surface of the mesh, while larger solid particles are intercepted. The relatively clear liquid then passes through the wire mesh and exits through the outlet.

This equipment is often applied in various industrial and production processes, such as wastewater treatment, food processing, chemical production, petroleum refining, and other fields. The use of a demister pad can effectively prevent interference caused by foam during the production process and improve the quality of the liquid.

SDP-01

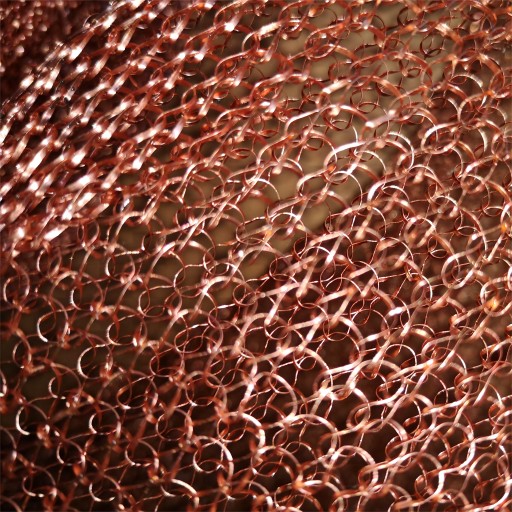

SDP-02

SDP-03

Materials

SS304、304A、316、316L、Monelse

Mesh Sizes

The wire mesh demister has a diameter range varying from 20 cm to several meters. It can be customized according to customer requirements, available in circular, square, or irregular shapes, all of which can be tailored based on provided blueprints. The wire diameter ranges from 0.1 to 0.3mm, and the density can be adjusted as per your needs. The maximum operating temperature can reach 300 degrees Celsius or even higher.

Properties Of Stainless Steel Demister Pad

1、High separation efficiency: The wire mesh demister utilizes a high-density fine wire mesh structure, which effectively captures and separates liquid particles and foams from the gas. This structure enables efficient gas-liquid separation in a relatively small space, resulting in a compact design and space-saving.

2、Low pressure drop: Due to the fine wire mesh structure, the wire mesh demister has lower pressure drop compared to other gas-liquid separation devices. This is advantageous for applications that require low system resistance and energy consumption.

3、Corrosion resistance: Wire mesh demisters are typically made of corrosion-resistant materials such as stainless steel or plastic, allowing them to operate stably in various corrosive gas and liquid environments.

4、Strong adaptability: Wire mesh demisters can be used in various process conditions and media types. They are widely used in industries such as chemical, petroleum, petrochemical, pharmaceuticals, and power generation.

5、Easy installation: Due to their relatively small size and lightweight, as well as the absence of complex support structures, wire mesh demisters are easy to install and can be flexibly applied in different engineering projects.